Customer profile

The HOMAG Group is the world’s leading provider of integrated solutions for production in the woodworking industry and woodworking shops. As a global player, the Group operates international production plants as well as sales and service companies. With around 6600 employees, HOMAG has a presence in more than 100 countries and an estimated global market share over 30%. The HOMAG Group offers its customers solutions for digitized production, based on digital data continuity from point of sale through the entire production process, combined with a comprehensive software suite. The range of machines and systems available extends from individual machines for trade businesses to complete, networked production lines for highly industrialized, individual furniture production.

Business challenge

In 1991, HOMAG had started the development of the woodWOP application dedicated to the programming of HOMAG woodworking CNC machines. In 2004, HOMAG understood that the fast growing industry required new approaches with the use of CAD technologies. Therefore, the company was looking for a partner for the development of a new versions of woodWOP, to implement CAD background into the application. And that was the start of a long collaboration between Open Cascade and the HOMAG Group.

One of the main challenges was to create a 100% parametric sketcher for the design of geometries. Such a sketcher could allow building a tool path in the so-called two and a half dimensions, where Z coordinate could be changed along the perimeter, modifying the depth of the tool work.

Further development included integration of CAD functions directly into woodWOP in order to allow users to utilize 3D CAD functions for the creation of 3D surfaces inside the application, align 3D models automatically, etc.

The expansion of the range of formats used in the industry required new CAD formats import and processing features: direct import of DXF diagrams with distribution of entities through layers; import of 3D CAD data in DXF, STEP, and IGES formats; import and processing of STL surfaces; import and editing of SAT surfaces; introduction of the new HOMAG proprietary MPRX format based on XML.

Implementation of a powerful 3D viewer to the application would allow users to rotate, translate, mirror and scale components and observe simulated machine programs in real time.

Due to a certain area of software application, it was required to add specific features for milling and woodworking based on geometry:

- New “spline” and “ellipse” contour definition elements;

- Direct text function in polygon path macro;

- Pocket milling with islands with offcut detection;

- Grooving and sawing on contours;

- Feature detection bore holes (cylindrical holes, conical, pockets and grooves).

In addition to all of the above, appropriate licensing conditions without any subscription systems were one of the most important requirements for HOMAG. At the same time, Open Cascade offered expert support and consulting along the whole way of project development.

Technology solution

Open Cascade appeared to be the best choice thanks to its proprietary full-featured open-source CAD library, deep geometry and topological expertise and ready-to-use components. Successful collaboration between Open Cascade and HOMAG led to the development of one of the best applications for woodworking machines.

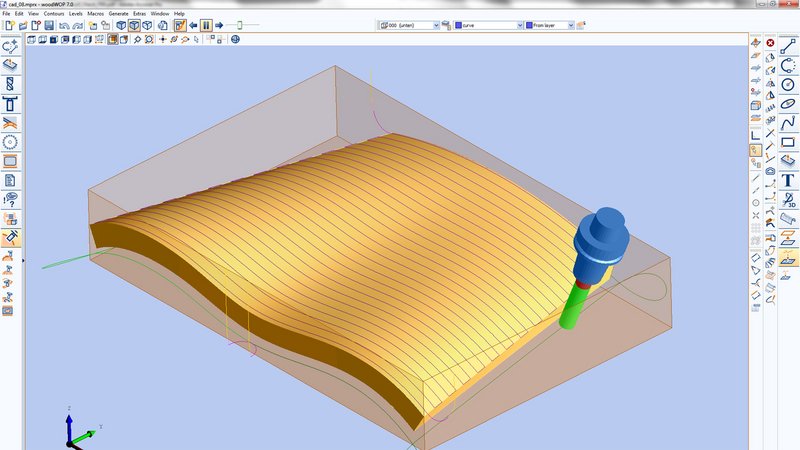

A sketcher based on Open CASCADE Technology allows creating sketches in 2.5D. The sketcher is fully parametrical and enables changing the values of variables, while modifying and recalculating the toolpaths and all associated points.

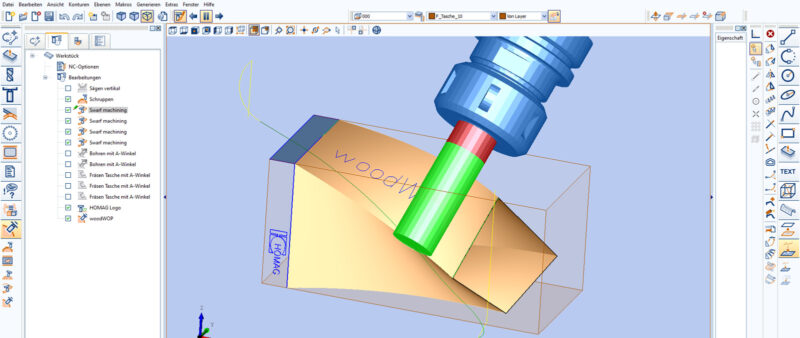

CAD plug-in based on Open CASCADE Modeling Algorithms directly integrates CAD functions into woodWOP and makes possible automatic simulation of milling paths from 3-axis processing right through to interpolating 5-axis processing and automatic sawing of surfaces in a 3D model. 3D objects can be built from sketches in order to completely generate the path of the tool, the way it will be driven by the machine. As a result, the user can anticipate collisions along the toolpath and see all machining operation parameters such as the tool number, the feed rate, the rotation speed, etc.

Open Cascade 3D viewer for visualization of the geometry and machining traces provides the user with the ability of viewing collisions, instrument toolpath, etc. in real-time.

Open Cascade Application Framework for parametric CAD and CAM functions was customized for HOMAG needs — shapes and operations, optimized function mechanism, a tree of variables, operations and sketch were added. The framework also allowed to implement a third-party CAM plug-in — a new macros for roughing down, finishing, and formatting of 3D objects.

Thus, today WoodWOP is a CNC programming system which interface is centered around the large graphics area. The workpiece, processing steps and clamping equipment are displayed in 3D. Trimming, bore holes and saw cuts can be programmed quickly and easily by entering the processing parameters, and can then be checked immediately in the graphics area.

Business value

Since 2004, the collaboration between Open Cascade and HOMAG has helped to extend the capabilities of the HOMAG development team by external skills with solid expertise in the world of CAD modeling, simulation and manufacturing. These expertise have made it possible to extend the functionalities of woodWOP in these areas at a controlled cost.

At the moment about 30.000 CNC machines worldwide are operated with woodWOP. In addition, more than 30.000 Office-PCs are also running woodWOP for the preparation of wood machining programs, so that in total, approximately 100.000 people worldwide are using woodWOP in 36 different languages. …woodWOP shapes to a great extent the woodworking industry.

- woodWOP allows users to create part programs very quickly and efficiently without having any CNC knowledge.

- woodWOP provides CAD basic functions for describing a workpiece geometry.

- woodWOP increases programming security through a 3D view of the complete working environment including workpieces, processing and clamping equipment.

- Open Cascade provides the technology to go further with CAD/CAM functionalities of woodWOP.

- woodWOP is an ongoing development project, very successful thanks to the excellent long-term partnership between HOMAG and Open Cascade.

Open Cascade successfully cooperated with CEA engineers to connect different kinds of hardware with different characteristics of communication protocols.

Development of a pre- and post-processing user interface for CATHARE code.

Open Cascade develops CAD and graphic kernel for Twin Robotics AppRob platform — the new generation of robotics software that combine several digital twins to simulate a maximum of sub-systems.