Customer profile

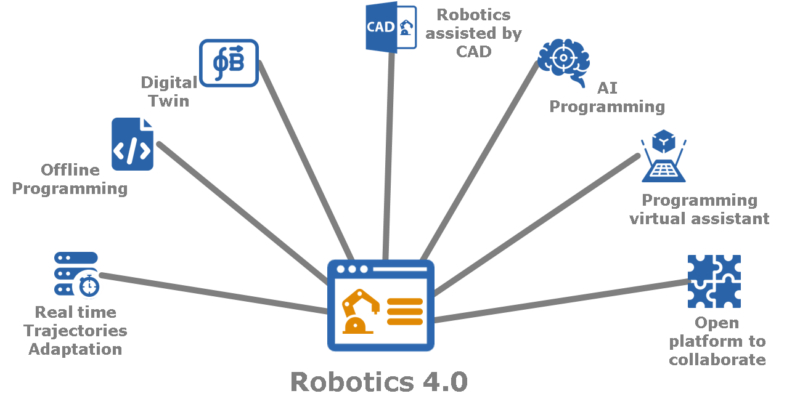

Twin Robotics SAS is a start-up located in Grenoble, France, it develops a robotics software platform including Digital Twin and Industry 4.0 concepts. The company’s owners are industry veterans in off-line programming, industrial robotics simulation and AI.

Business challenge

3D Digital Twins represent a handy way for manufacturers to manage the performance, effectiveness, and quality of production assets. Simulations of robotic manufacturing or quality assurance processes reduce efforts for integration of new equipment into the existing environment and globally minimize preparation or modification time for various-purposed robotic equipment.

An industrial robotics workcell is made up with several sub-systems. The Digital Twin of the robot is the most obvious object for an offline programming and robotic simulation software. But what about the tool handled by the robot, and the part that interacts with the tool? Do we need another software to simulate them? Twin Robotics is working on the new generation of robotics software that combine several digital twins to simulate a maximum of sub-systems. But if it possible to simulate, it is possible to make decision based on measurement. This is the first assumption of the AI and it opens a huge field of the AI robotics programming.

For the first stage of the project, Twin Robotics was looking for a technology partner that could develop CAD and graphic kernel of the application. Open Cascade, with its deep geometric expertise and own 3D modeling kernel (Open CASCADE Technology), at the same time offering the most modern solutions and constantly developing its technologies, turned out to be the right choice for the challenge.

Creation of initial architecture and environment, utilizing of OCCT visualization, modeling, Boolean operations, etc., comprised the scope of Open Cascade participation in the first stage of AppRob. Twin Robotics in parallel is developing the robotic-specific features and the result of the collaboration will be a cutting-edge solution combining robotic kinematics, CAD and visualization technologies.

Technology solution

Almost all parts of Open CASCADE Technology have been used for the development of this application: modeling data and algorithms for creation and modification of 3D models, data exchange for import and export of CAD formats, application framework for data structures management, visualization for working in 3D viewer and simulation of robot motions. Open Cascade has elaborated the base for displaying robotic kinematics that will be further complemented with robotic-specific features and transformed into AI robot programming platform by Twin Robotics.

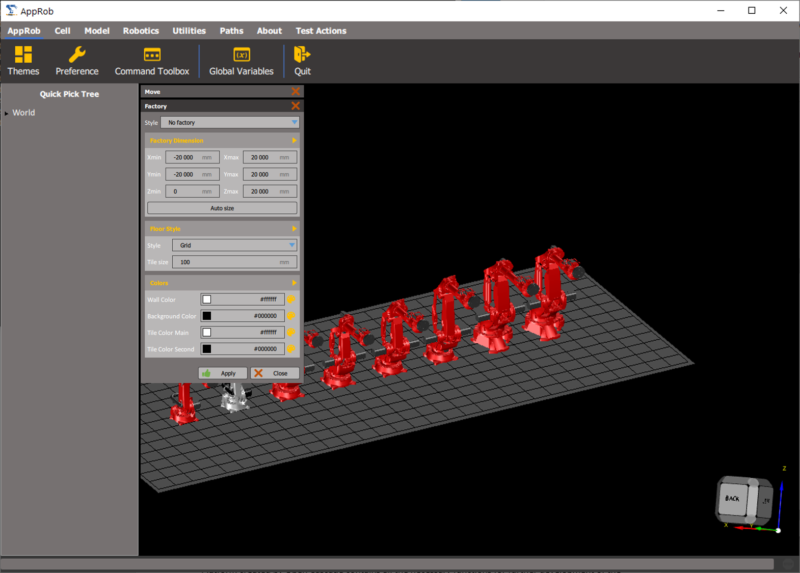

DMU Reviewer — a high-performance CAD viewer offered by Open Cascade — was supposed to be the basis of the project design. The specific requirements of Twin Robotics for the future application led to the necessity for custom development and evolution of this basis design into a new unique end-user application.

The result of the year of cooperation between Open Cascade and Twin Robotics is the birth of a platform with convenient user interface and wide feature set comprising of the following:

- Import and export of external CAD file formats (STEP, IGES, STL, VRML) as well as support of native documents format, including “Drag and drop” functionality for supported files in graphical user interface (GUI);

- Creation and positioning of CAD object for modeling directly in the application;

- Geometric and mesh measurements;

- Boolean operations between geometrical and mesh objects;

- Browsing structure of sub-elements of the model and management of its content and properties;

- Interface customization: support of themes setting by user, customization of the ribbon menu, shortcuts;

- Support of different display modes for 3D models, visualization of working environment in 3D view, selection and other 3D view management.

Open Cascade has also provided an API for adding animation of the robots’ movement, planning of such movements, etc. to support further development of Twin Robotics.

Business value

The worldwide business for Digital Twins was $3,5 Billion in 2019. Experts says it will surge to $38 Billion in 2023.

The first phase of AppRob project for AI robot programming is now complete. The part of the Robotics Platform created by Open Cascade contains all the necessary functions for further development of the platform.

In the second phase of the project, Twin Robotics is planning to develop the robotic-specific kernel of the application (multi-agent Digital Twin) and Open Cascade is going to support the company as a consultant in CAD related issues, algorithmics, Open Cascade Technology application, etc.

Development of a semi-automatic graphic preprocessor to meet the specifications imposed by the computational fluid dynamics solver used at BMW.

Open Cascade helps HOMAG to enhance woodWOP, the application for the programming of CNC machines for woodworking, with 3D CAD technologies.

Open Cascade successfully cooperated with CEA engineers to connect different kinds of hardware with different characteristics of communication protocols.